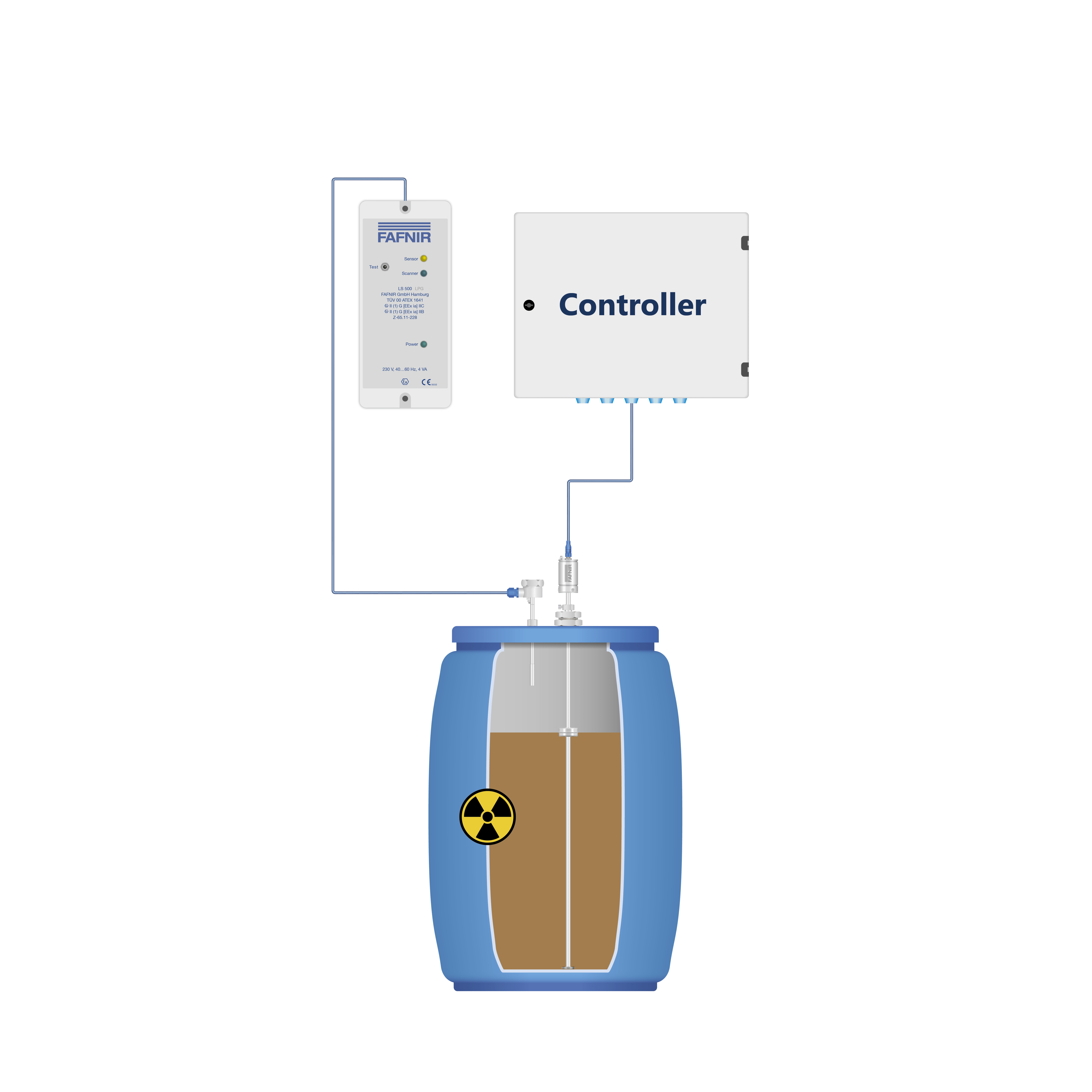

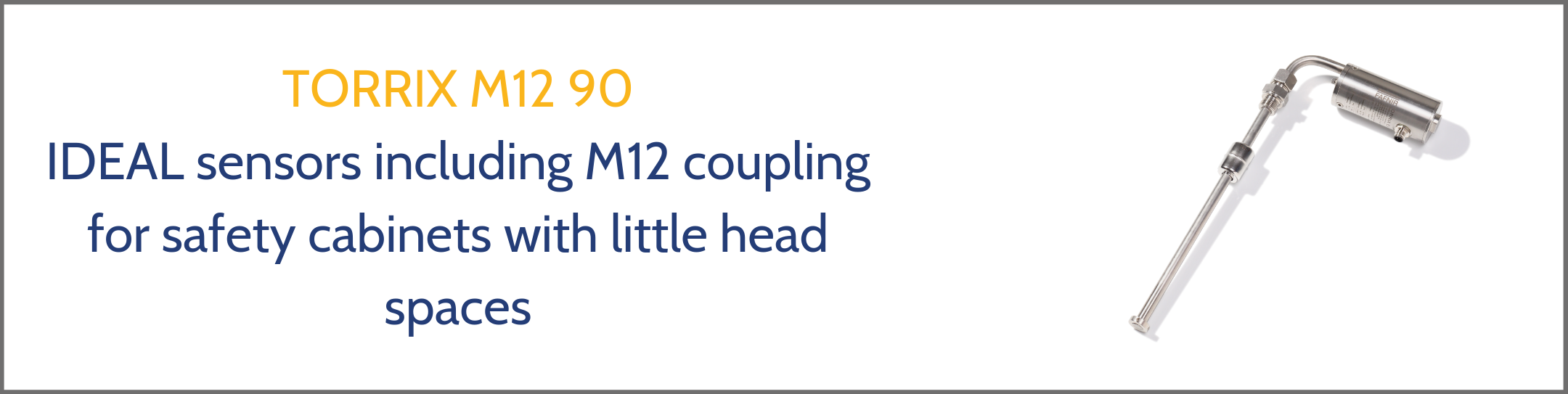

The TORRIX M12 90s sensor head bends by 90° which reduces the needed head space significantly. The best solution where head space is limited, i.e. for barrels stored under a table or in a safety cabinets.

- M12 coupling for fast mounting

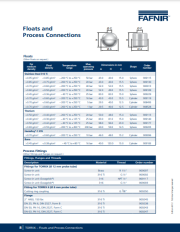

- Length: 150 mm up to 1000 mm

- All standard fittings available

- Process temperature of up to 85 °C.

- Process pressure up to 120 bar

- Available with 4 to 20 mA, 4 to 20 mA / HART, RS-485 interface and serial FAFNIR interface

- ATEX and IECEx approval for use in Zone 0

Applications

Accessories

HPH Ex d

High Pressure Connection Housing

- On site display for level indication

- Corrosion resistant (stainless steel 1.4305)

- Adjustable display

- 10 mm LED display

- Easy to install

- Intrinsically safe power supply for Ex-Zone 0

- ATEX and IECEx approval

- Robust design

UM-X

The control unit in a field housing for continuous level sensors

- Easy menu-driven graphical user interface

- Can be used with all sensors with a 4-20 mA interface

- Intrinsically safe electrical circuit with ATEX approval (Ex ia)

- Combined with TORRIX, approved as an overfill prevention

- fulfilling the German Water Resources Act (WHG)

- Pump control (alternating)

- Continuous displaying the filling level

- Filling levels can be displayed in mm, inches, % or mA

Ex REPEATER/POWER SUPPLY

PR Electronics PRetrans 5104B

- Current loop : <28 V, max. 600 Ohm

- Output : 4 - 20 mA

- Auxiliary power : 24 - 230 V DC/AC

- Hilfsenergie : 24 bis 230 V DC/AC

- Snap-on mounting for DIN-rail

Application Examples

Below are examples of where the TORRIX is being used successfully

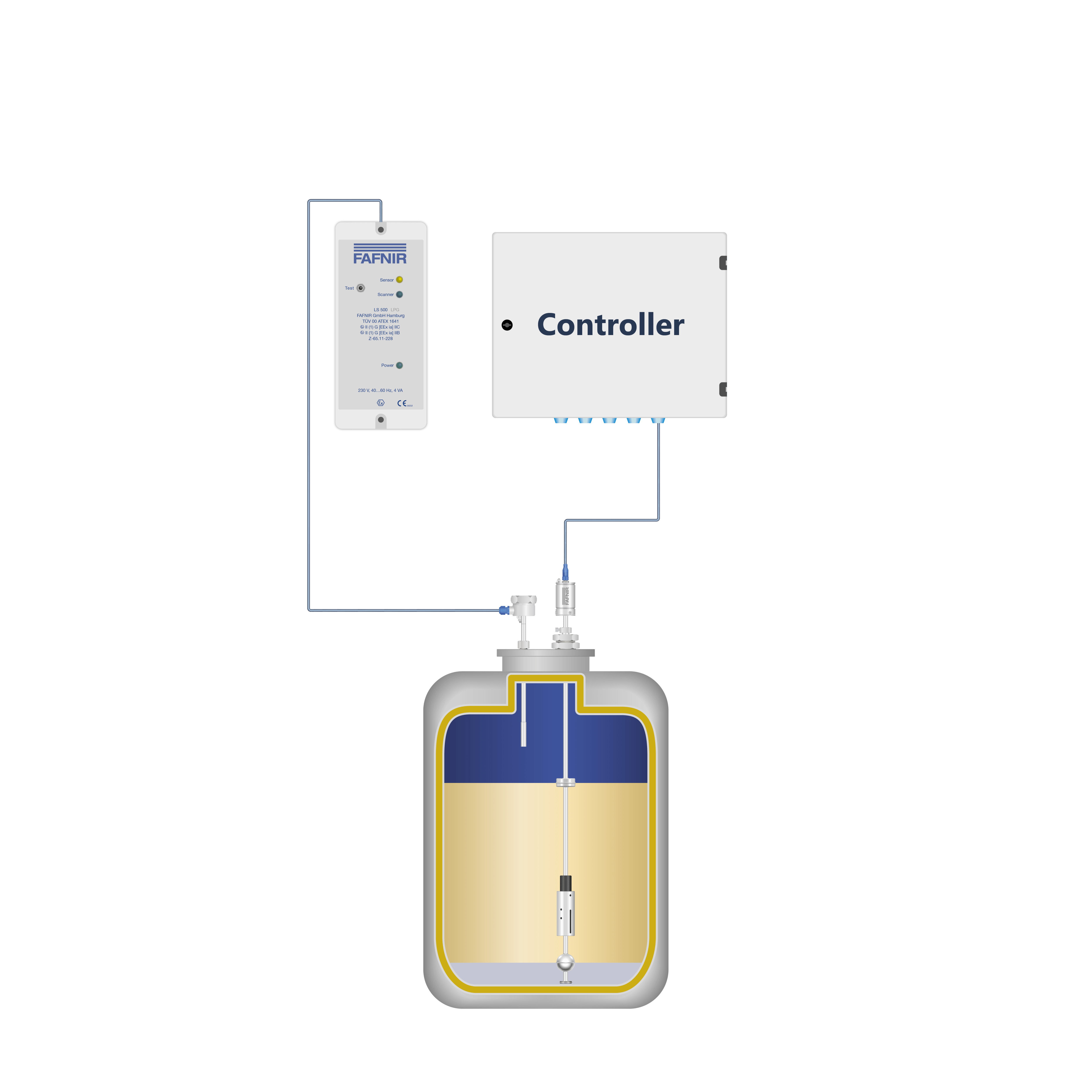

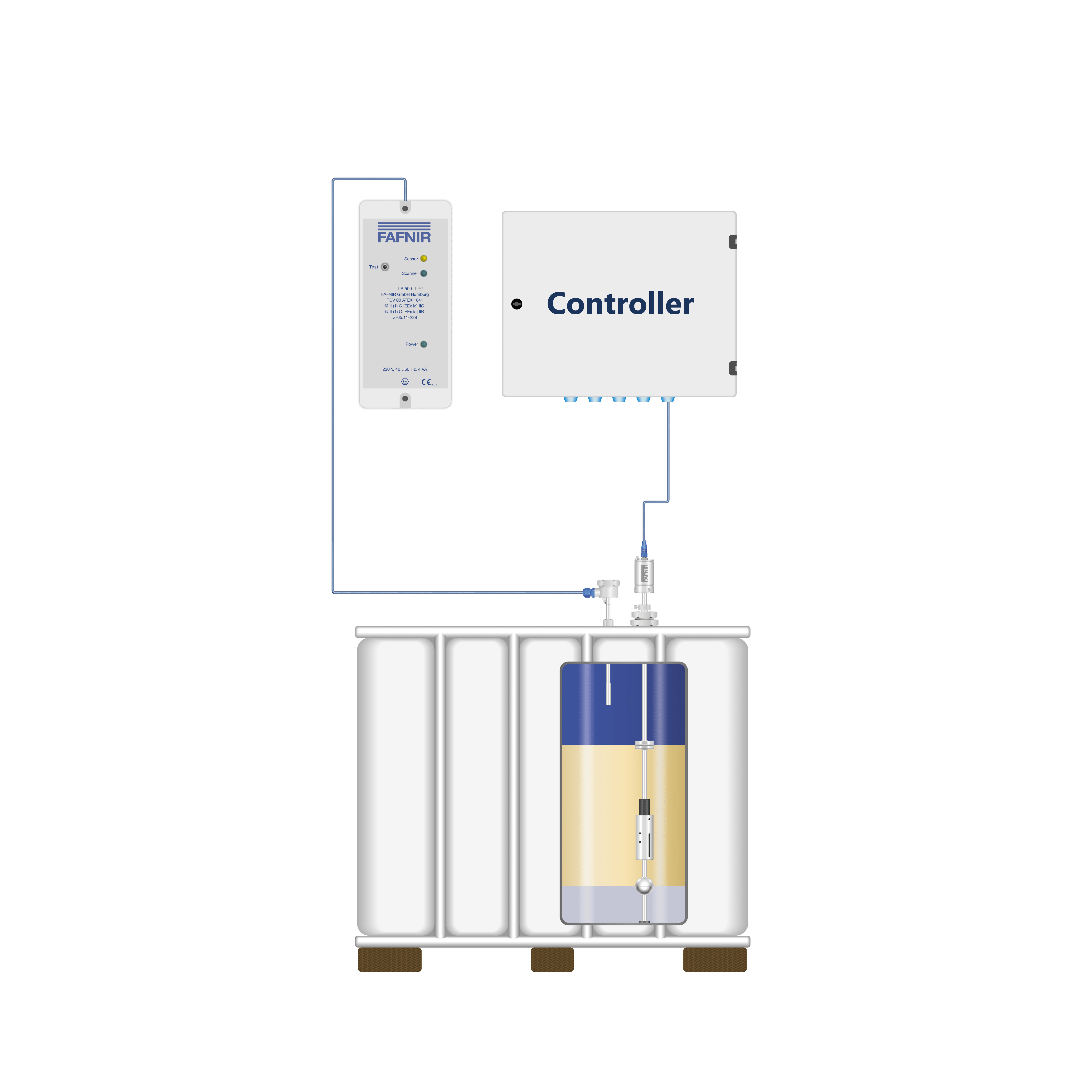

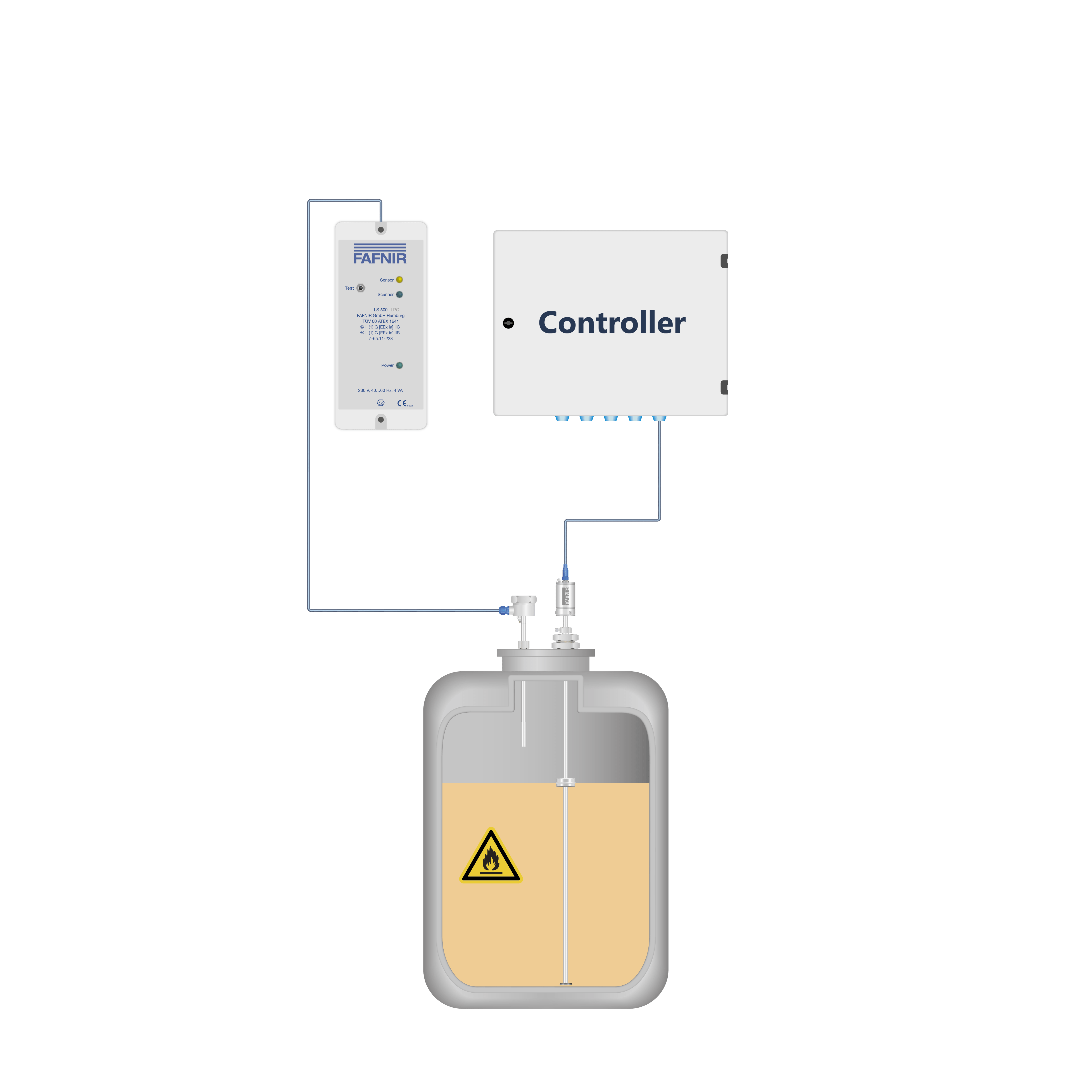

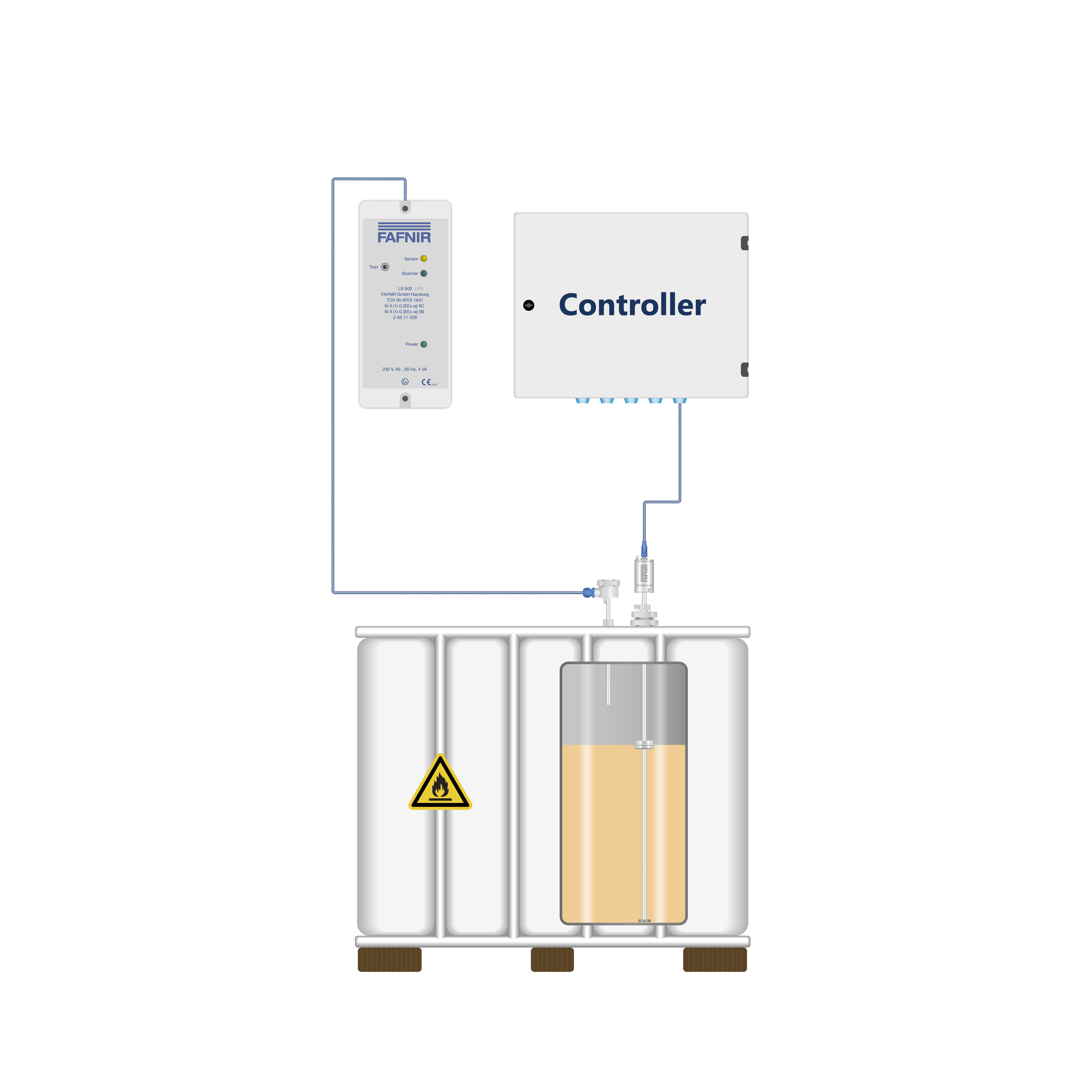

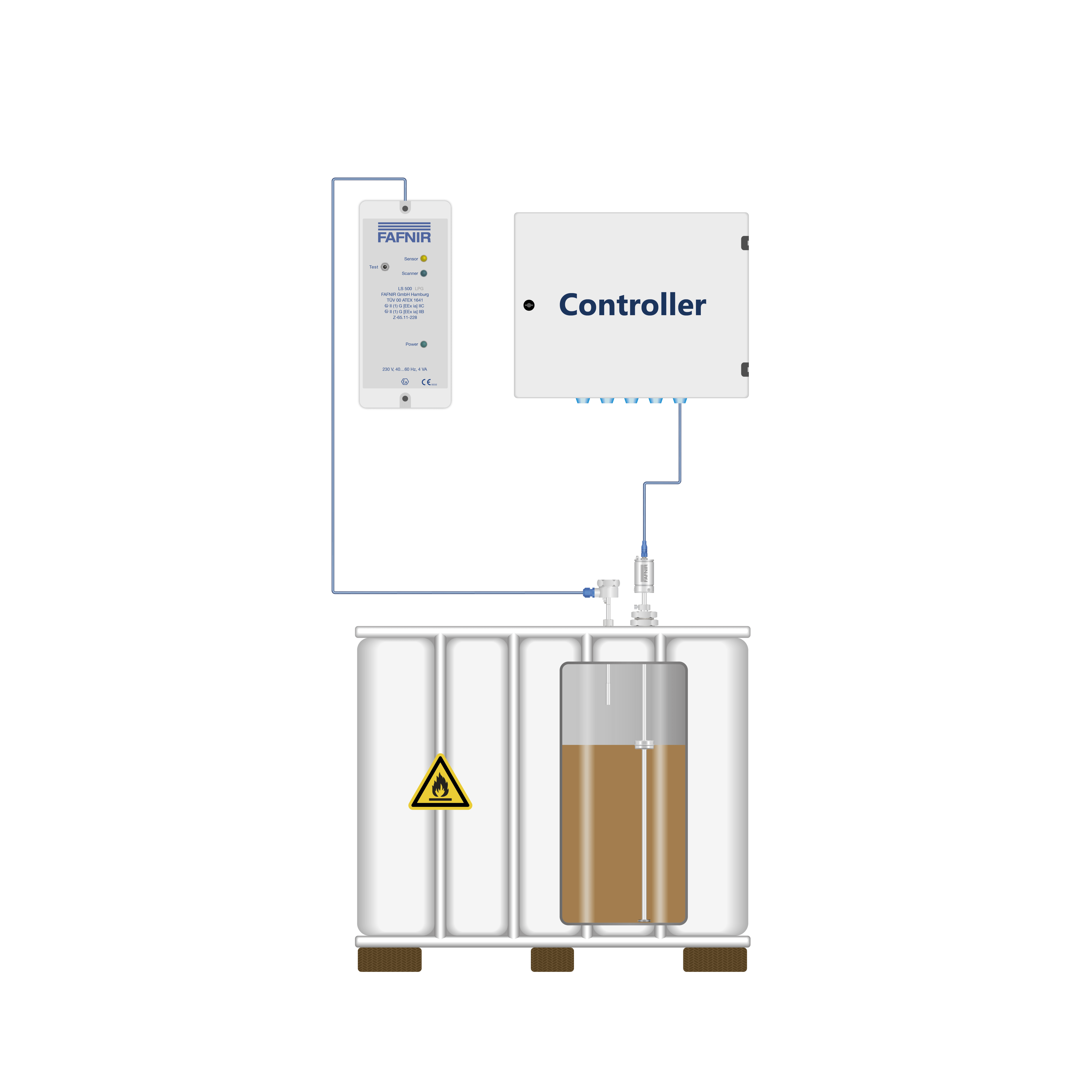

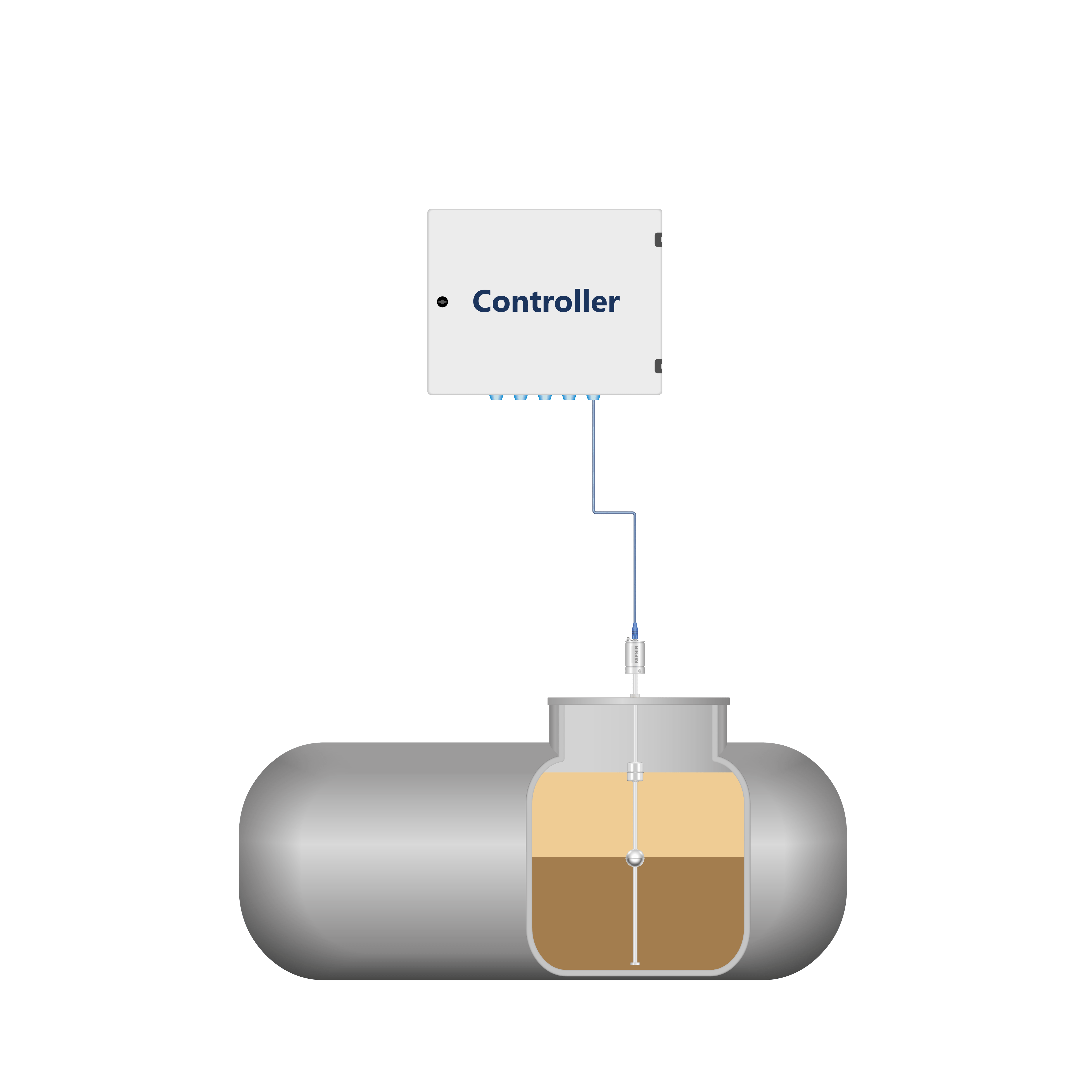

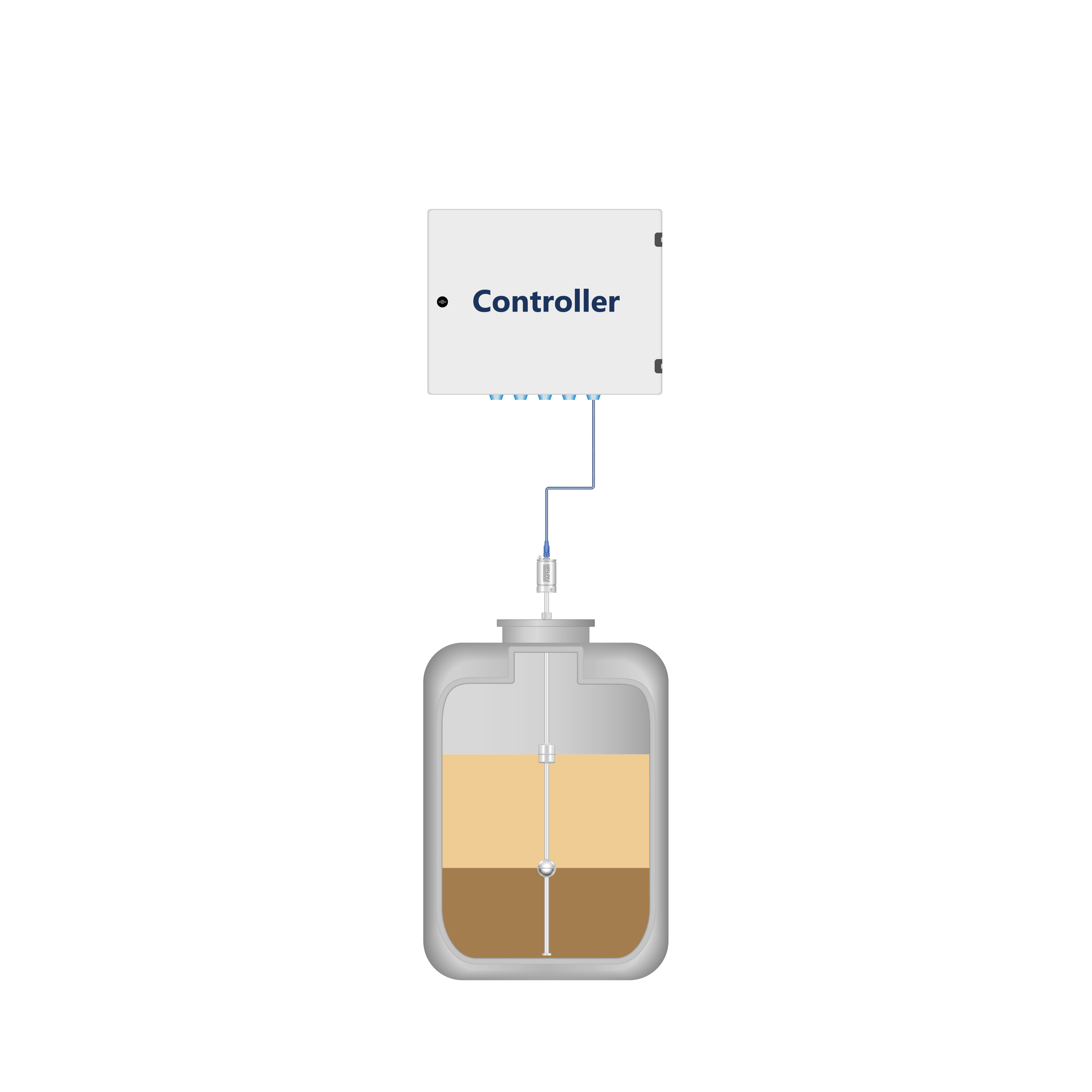

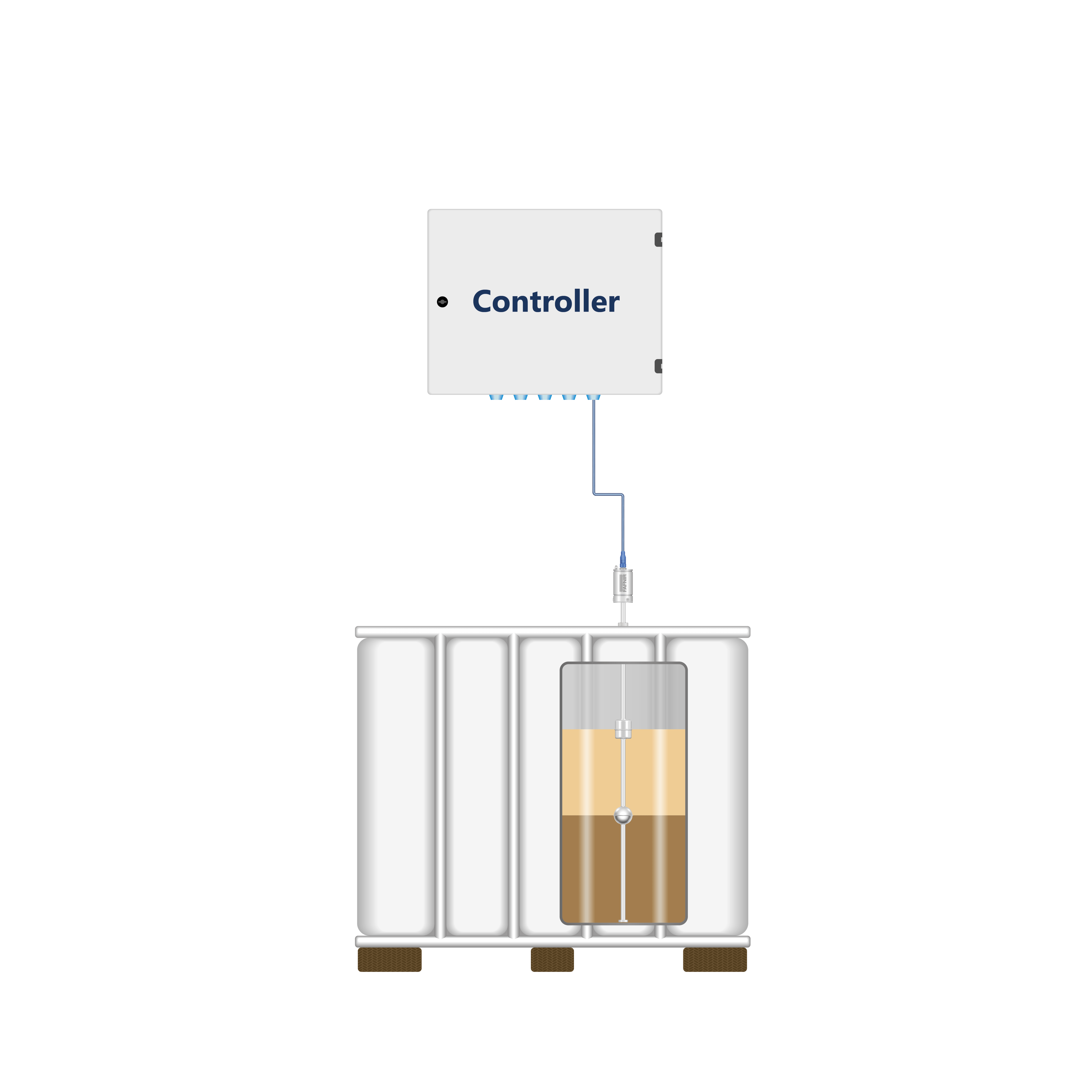

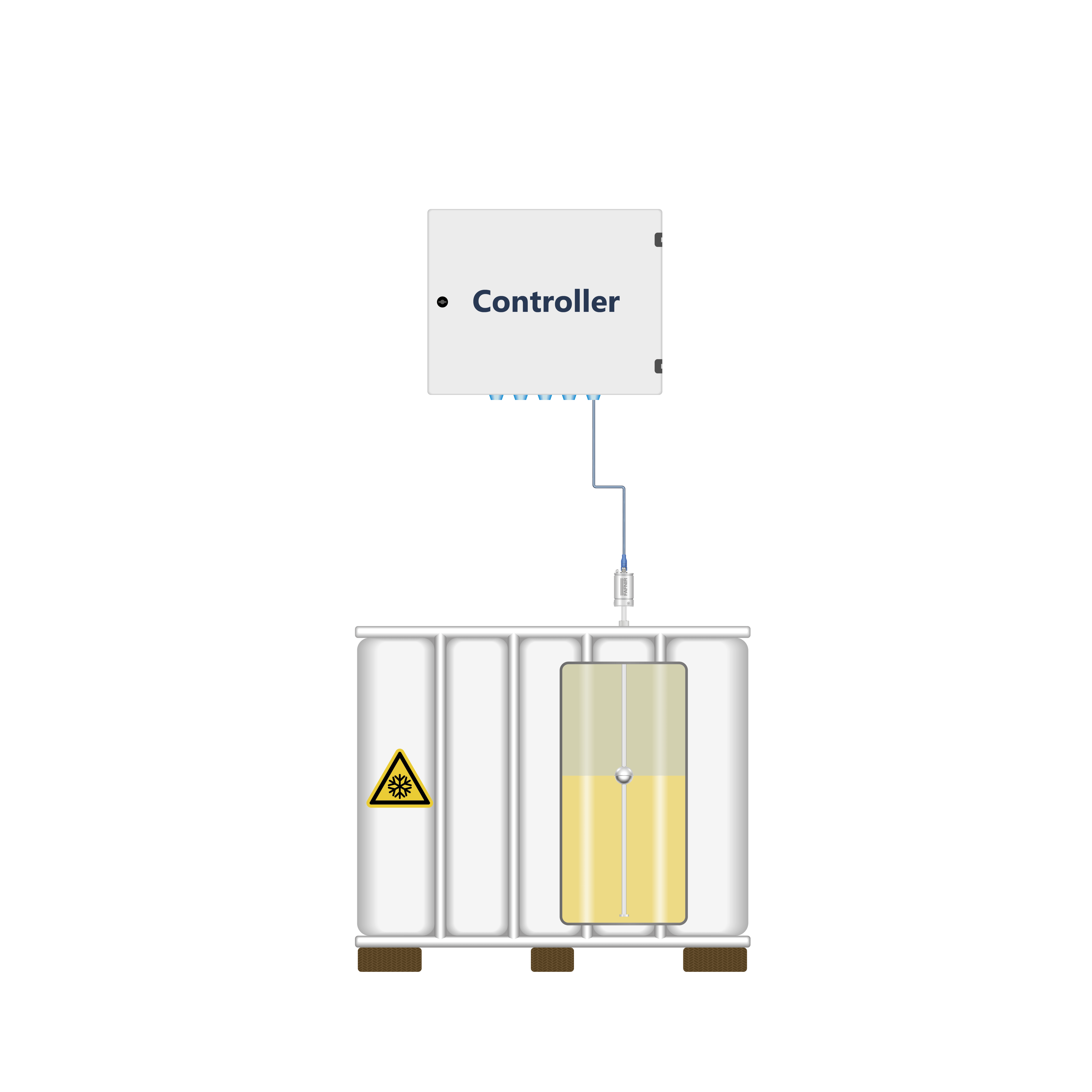

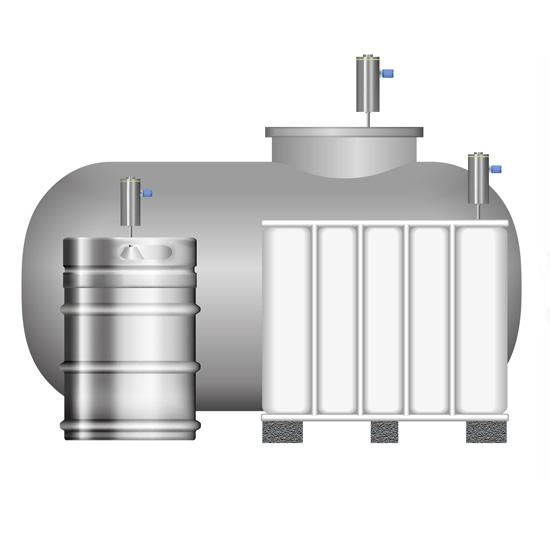

Storage Tanks and Storage Containers

TORRIX is ideally suited for measuring in all non-adhesive liquids and almost all tank geometries. There is no need to adjust the sensor to the liquid or the shape of the tank. Another advantage is that there are no dead zones in the upper and lower areas. The starting point of the measurement is only defined by the size of the float; therefore the entire volume can be measured and used.

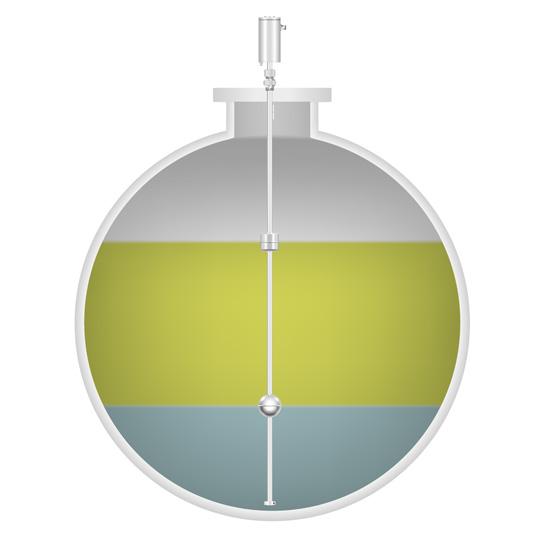

Interface layer measurements where emulsions are present

When used with HART ® protocol, TORRIX can measure both the interface level and the overall level of a tank. Unlike sensors that operate on the guided microwave principle, the interface layer can be easily recognized even when emulsion is present.

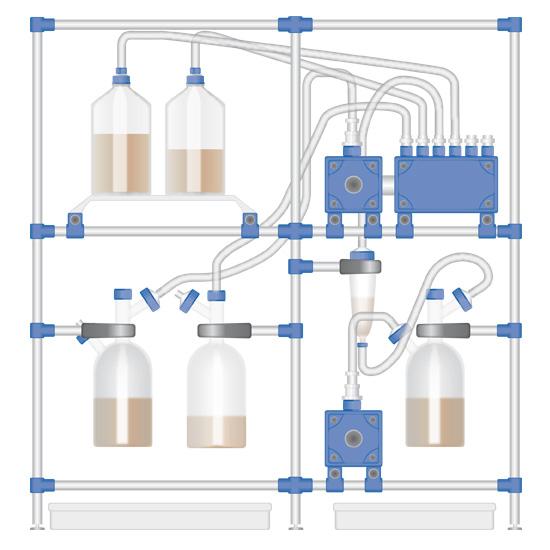

Pilot plant and prototype systems

The TORRIX 6 with his probe diameter of 6 mm and float diameter of 27 mm is ideal for applications in smaller containers. Unlike most sensors, TORRIX measures in the upper and lower region with no dead zone with the threshold point defined only by the float. The TORRIX is ideal in applications where frequent changes of media are needed as it does not require adjustment.

System with toxic chemicals

The TORRIX can be welded gas tight with any flange and reduce the potential for leaks in your system less. This allows TORRIX be used in processes with hazardous fluids such as ammonia.

Highly accurate measurement, ideal for dispensing volume

With an accuracy of up to 0.3 mm, TORRIX can be used for precise level measurement allowing leak detection in small storage tanks.

In combination with a metering valve, the liquid level measurement feature can also be used to fill a well-defined volume in a process tank. Depending on the geometry of the tank, the accuracy with a filling volume of 100 ml is as low as 2%.

Such is the accuracy of TORRIX, it can also be used in a calibration rig to check the accuracy of other level sensors.

Bypass applications with magnetic level indicator

In magnetic level indicator applications, the magnetic indicators are actuated by the magnetic field of a float in the interior of the bypass. The magnetic field of this float can also be measured by a TORRIX which is mounted on the exterior of the bypass. The TORRIX can therefore measure the level without media contact and without additional intervention in the process tank. Many magnetic level gauges can be retrofitted with a TORRIX.

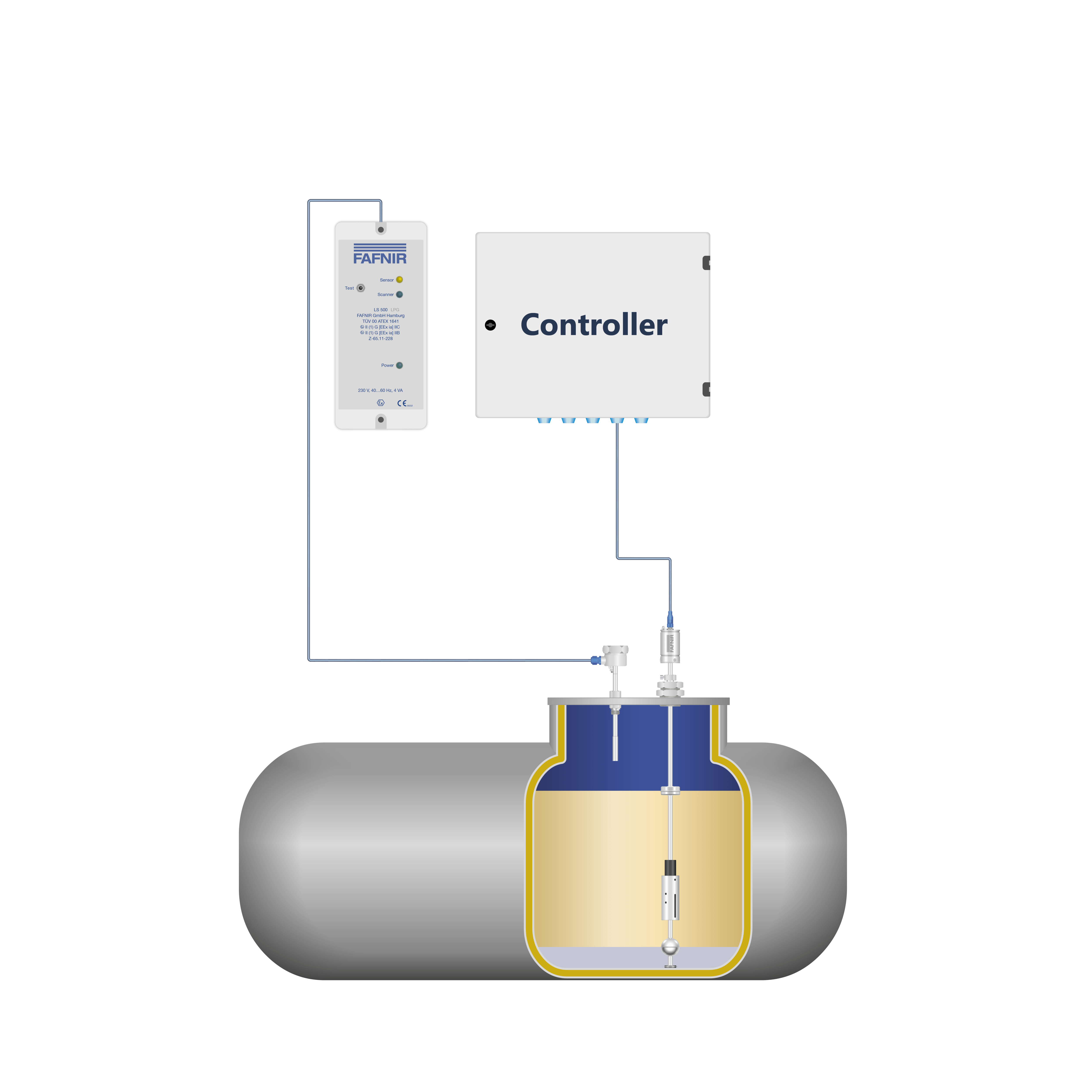

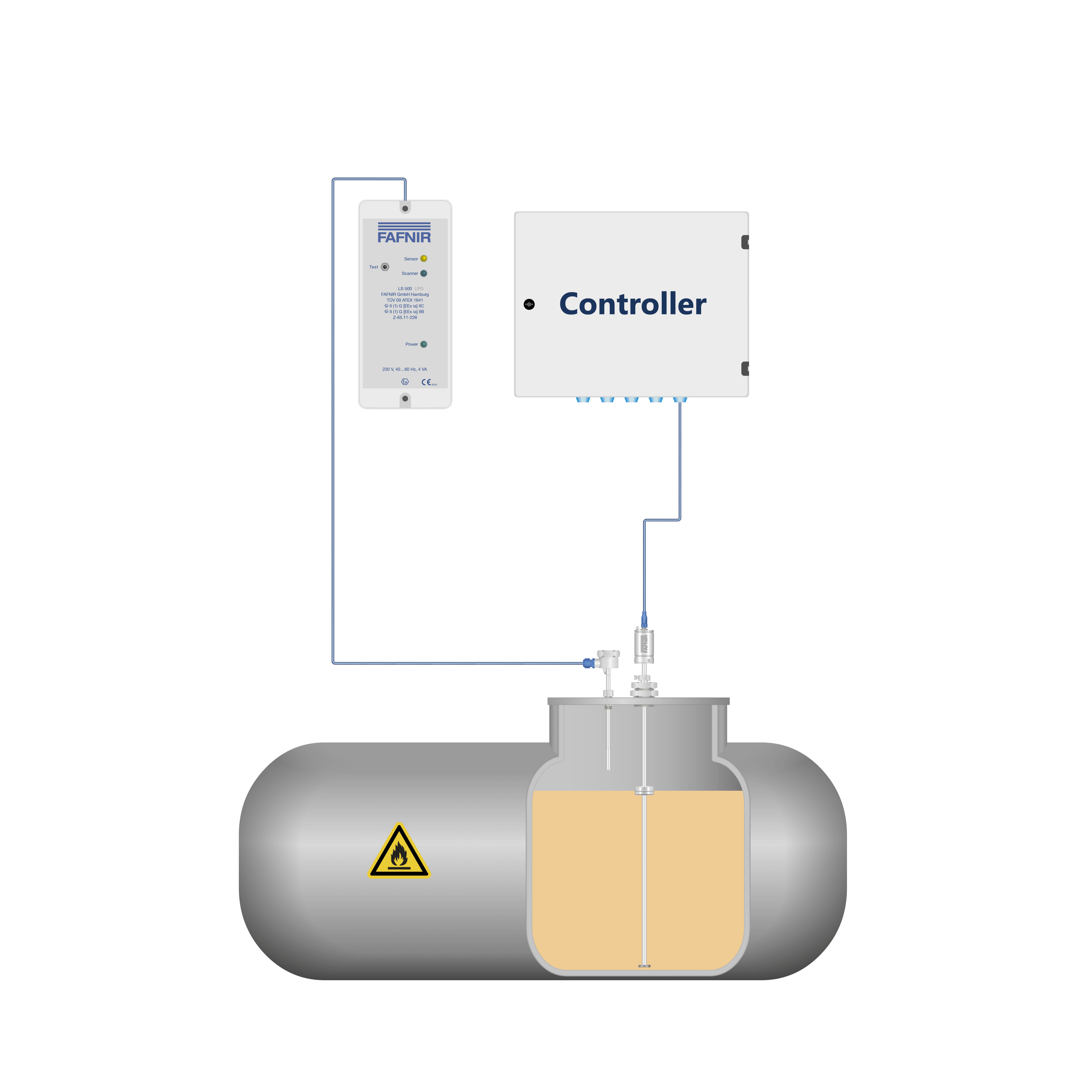

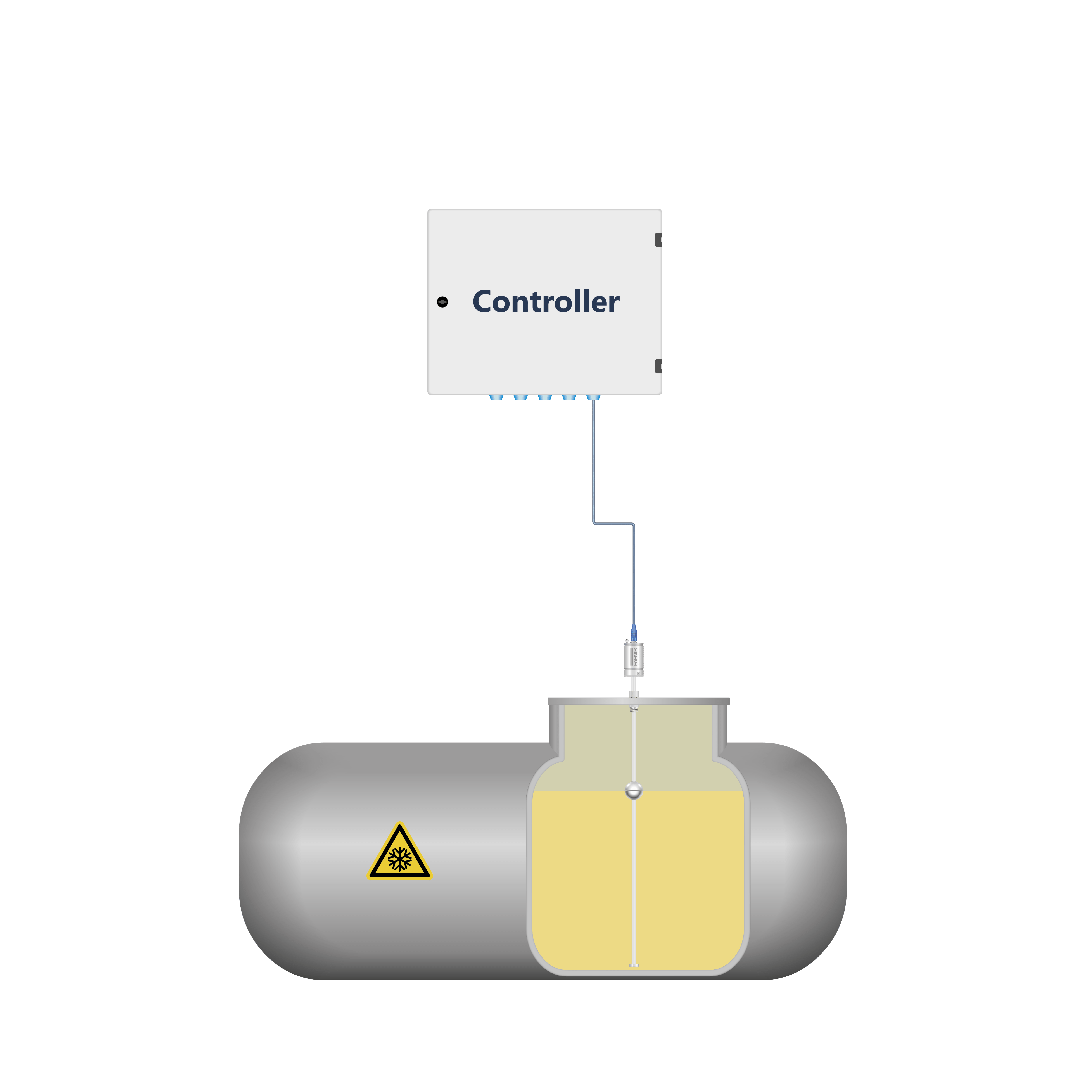

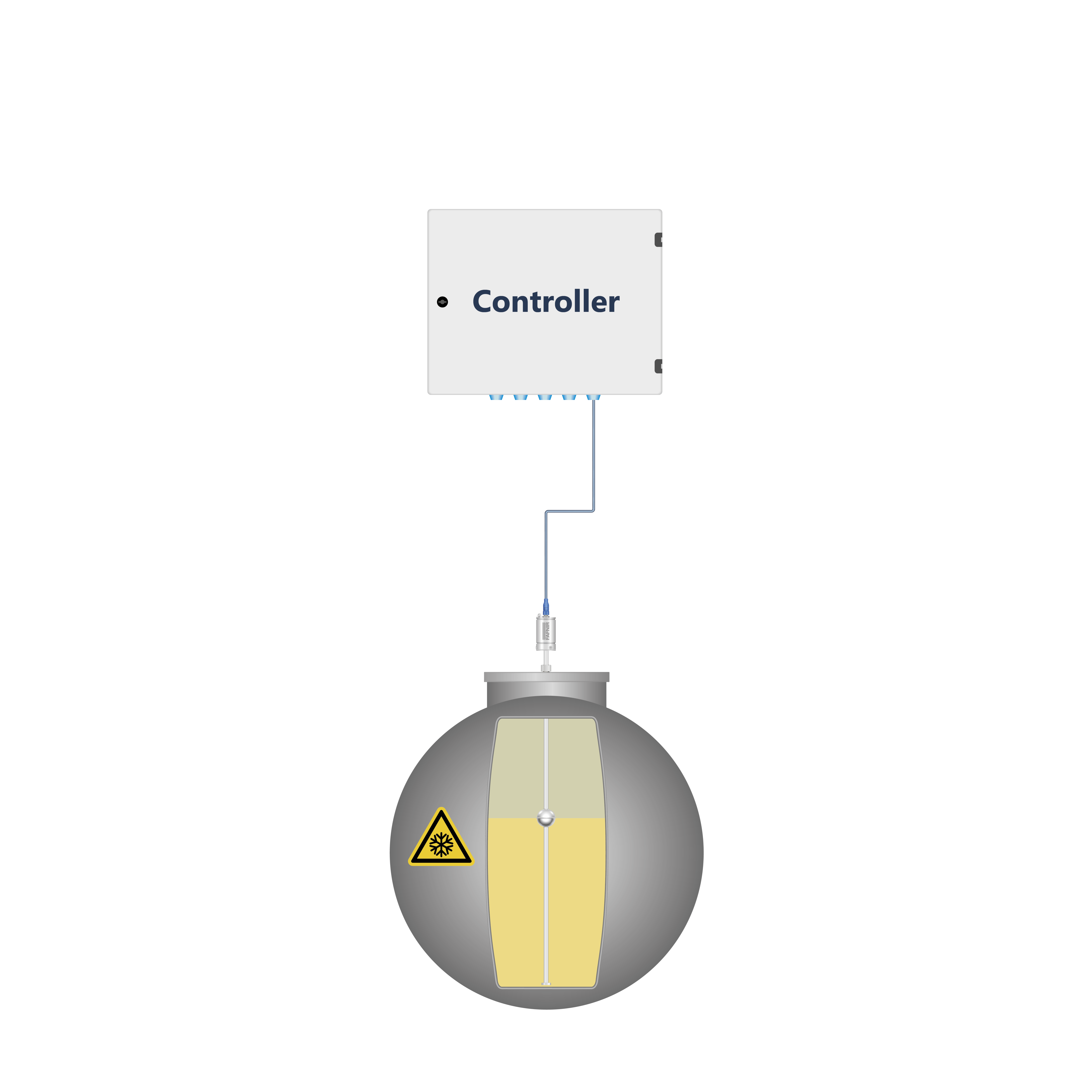

LPG and other pressurized tanks

With the LPG BUNA float installation kit, TORRIX can also measure the contents of an LPG tank. The sensor is not fitted to the pressurised space (zone) in the tank which means that the fitment of a sensor is possible without opening the tank. Level measurement by TORRIX is performed independently from the manufacturer installed sensor. The principle of the installation kit is not only suitable for LPG, but for all pressurised tanks

Contact Information

Sales Engineer

Kevin Biehl

Phone: +49/40/39 82 07 - 83

Fax: +49/40/390 63 - 39

E-Mail: kevin.biehl@fafnir.de

Customer and Technical Support

Michael Stier

Phone: +49/40/39 82 07 - 14

Fax: +49/40/390 63 - 39

E-Mail: michael.stier@fafnir.de

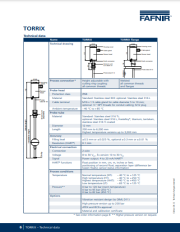

Specifications

| Equipment Type | Magnetostrictive Level Measurement |

|---|---|

| Liquid | Chemicals, Fuel, Solvents, Water |

| Vessel | Intermediate Bulk Container (IBC), Waste Container |

| Measuring range | 150.00 mm up to 1 000.00 mm |

| Stem diameter | 12.00 |

| Process Connection | None |

| Temperature | -40.00 °C up to 85.00 °C |

| Pressure | -1.00 bar up to 120.00 bar |

| Certification | ATEX, IECEx, None |

| Signal output | 4-20 mA, HART, RS-485 - FAFNIR Protocol, RS-485 - MODBUS (ASCII) |

| Power Supply | 10 to 30 VDC, 15 VDC, 24 VDC |

| Additional criteria | Dry run protection, Electropolished, For low ceiling height |